UnitorK is our high precision intubation set for reflection optics, a compact and high-performance solution.

All design parameters have been extensively studied to give optimized results, which allow the full exploitation of your optical system, no matter how sophisticated or demanding it might be

.

In order to guarantee the best performance ot the optical set up, we recommend only high precision engineering.

The precision is provided basically by higth tolerances but also by an accurate design project which foresees the points which can generate flexions, twists and transmission of dangerous vibrations into the tube. NortheK has made the tubes of its reflectors instruments following a clear, simple, economical design with a no-frill look as you would expect a precision instrument to be.

The material used are Halo 25 aluminium and its variants, steel, carbon fiber, Ergal alloy, technopolymer with self-lubrification matrix. Each component of the UnitorK tube is made with the best material for the purpose. There are no plastic or laser-cut parts or multicoloured anodising which, although visually good, they do not give adeguate precision. UnitorK has precision, solidity, a nice look and a competitive price compared to a similar quality product. Improved performance at lower costs! UnitorK is not only a NortheK brand but a long term committment to design, study and research in projects using the latest software engineering. Having studied all the applications for this instrument, the Maxproject Team has worked out the optimum quality that it should have for both amateur and semi professional use, in this way the end-user can always be assured of the best performance in any conditions.

|

|

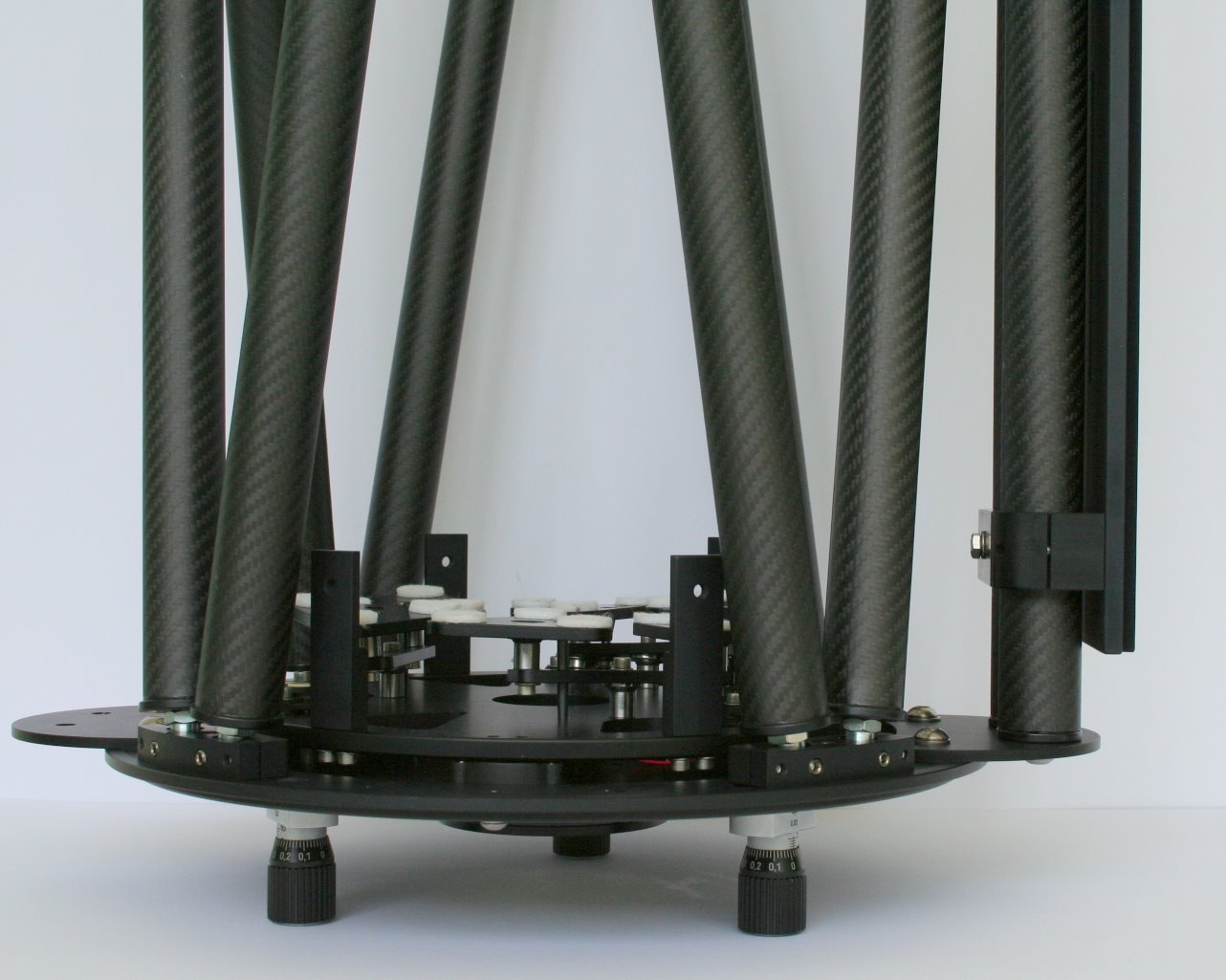

UnitorK has been entirely made using precision engineering, there are no moulded components, bolts and screws are stainless steel, other metal components are always machined to specification in order to ensure flatness, thickness and size within tight tolerances. The performance of your telescope relies on this precision. Our task is to deliver the optical beam exactly where and how you need to find it!

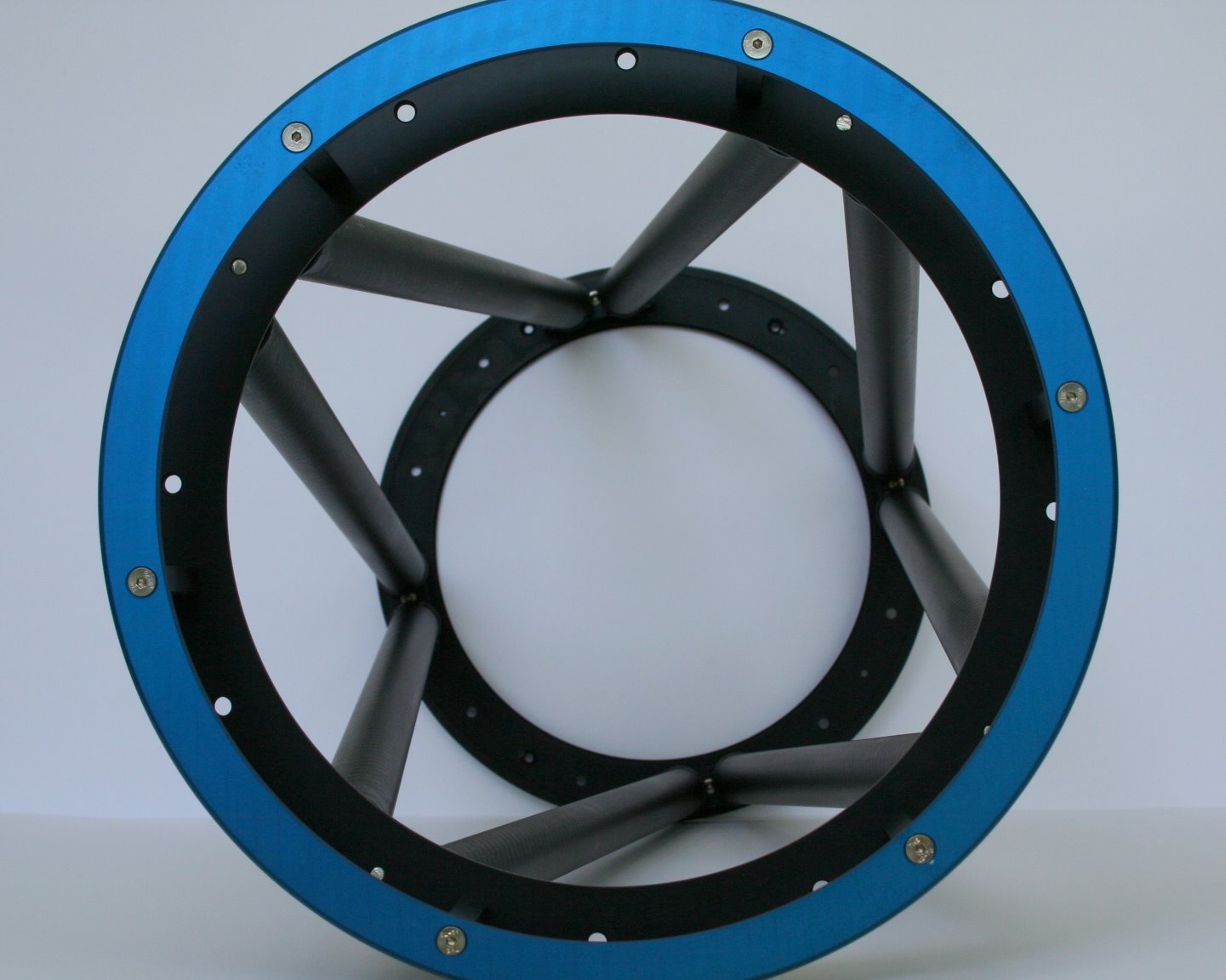

The carbon fiber is the essential component in the construction of the UnitorK tube. The technologically advanced know-how of NortheK allows them to supply extraordinary high performance tubes thanks to the specially developed lamination of the carbon fabric and wrapping techonology. Temperature controlled curing, hight-tech resins and anti UV gel coat make UnitorK tubes among the best for precision applications. Each UnitorK tube comes with a certificate of quality and origin of the carbon fiber. UnitorK can be purchased as it is or made to order, completed with NortheK high precision cells StabilobloK and AxyS and professional 2″ Feather Touch 2000 focusers. It is also possible develop special alterations to satisfy any special requirement. UnitorK can come in a “naked” version – for those who prefer the classic, totally open Serrurier – or in a “closed” version with a pipe, also totally made in thin carbon. For the “close” version it is possible to include forced ventilation system near the optical surface to cool down the glass surface quickly (this fast cooling option is useful only for those who do not have the time to acclimatize the telescope, as glasses are thin and a standard rear ventilation is already provided). UnitorK come with carbon fiber joints AS01. Upon request it is possible to supply the better performing AS02 which will be designed specifically for the optical scheme.

| Support rings | Halo 25 alloy |

| Dimensional tolerance on supports rings | less than 0,1 mm. |

| Ball joint support | Halo 25 alloy |

| Dimensional tolerance on ball joints supports | 0,1 mm. |

| Ball joints | chrome steel |

| Rear plate | Halo 25 alloy |

| Planarity of the rear final plate | less than 0,1 mm. |

| Nuts and bolts | Stainless steel |

| Carbon fiber truss tubes | 100% carbon, manufactured whit wrapping technology |

| Type of carbon fiber tubes | sandwich, manufactured whit wrapping technology |

| Type of sandwich | original design |

| Surface treatment of carbon tubes | grinding and protection with anti UV finish |

| Endings of the carbon tubes | Halo 25 alloy |

| Internal tube of the truss structure | 100% carbon, manufactured whit wrapping technology |

| Focuser connection | Halo 25 alloy, flattened within 0,1 mm. tolerance/accuracy |

| Ovalization of UnitorK | 0,1 mm. on the worked/tooled parts, 0,0 mm. induced |

| Forced ventilation of optical surface | |

| UnitorK horizontal flexion | too small to be measured |

| specifications may change without notice | |

| Product code: UNITORK 25 | Sale unit: linear meter |

Note: the tube is sold by the metre, UnitorK ALREADY comes with side supports for the axial connection to the axis and the movement translation system for the AxyS support or similar. Do not hesitate to ask further details to info@northek.it

UnitorK is a modular design from NortheK. It has been developed as an essential component for intubation of 250 mm. reflector telescopes.

The UnitorK design is available in various options, depending on the size and the application required. It may be adapted to fully open, partly open or closede Serruriers, using the truss as structure reinforcement.

UnitorK can be adapted to a wide range of diameters (from 250 mm. to 800 mm.) and mounts (German equatorial mounts, fork arms, or single arm forks). The carbon fiber is an essential design component, but for very large structures it is also possible to use metal only.

UnitorK can be used for refractor telescopes of large diameter and focal lenght. It is simple and economic solution, designed to exploit the maximum performance from your telescope.

Carbon fiber.

UnitorK has been built using carbon fiber. For industrial reasons, in small diameters (200-400 mm.) carbon fiber has been used only for the main components controlling the thermal expansion of the telescope. This is because the use of carbon fiber doesn’t aim to reduce the total weight (for this kind of products it will only reach the 12-15% less than a same quality metal instruments) but to improve the mechanical stability of your O.T.A..

UnitorK has the advantage of maintaining the light cone throughtout the observation session and when it is used in pair with the mirror cells StabilobloK and AxyS it allow a highly productive and enjoyable experience.

The carbon fiber is excellent for this kind of application, especially when it is manufactured having in mind the final product and the needs of the end-user. The NortheK lamination sandwiches are manufactured whit unidirectional fabrics, using high module fiber as well. For some special cases, it is possible to use high module carbon fiber only. Obviously, we use high-tech materials when they make the difference, otherwise we try to control the final price to the customer as long as ths doesn’t affect the telescope performance.

Metal parts.

Every metal part is CNC machined starting from milled cast blanks. This technology assures outstanding results and precision tolerances.

Whenever it doesn’t compromise the product performance, we always use aluminum alloys for standard diameters in order to reduce cost and weight. Obviously, in case of large customized instruments, it is also possible to use Mn and Cr alloy steels which have outstanding thermal and mechanincal properties. The cost of these high performing materials being very high, in terms of price and cost of manufacturing, they are used exclusively for high budget projects and instruments to be installed in a fixed observatory.

The use of these steels when when joined to some aluminum alloys and carbon fiber guarantee a high-performance, top quality instrument.

Mounting and testing procedures within tight tolerances for every single instrument allow actual tolerances to be very close to the nominal ones.

Nuts and bolts.

The standard nuts and bolts are stainless steel or Ergal alloy.

In case of special project we can supply nuts and bolts using steel and tolerances to your own requirements. The aim is to achieve maximum precision and performance during use. In these cases we normally use high-precision threads (UNI H7).

Self-constructors.

UnitorK comes complete, assembled and centred for self-constructor amateurs.

UnitorK includes alloy rings (as well as the terminal one for the support of the secondary), holes and threads to add StabilobloK and AxyS. These holes also allow the attachment of your own cells or stands for the secondary.

UnitorK obviously includes a carbon framework, but it doesn’t incorporate the complete inner tube which should be purchased separately. The maximum lenght available is 1,20 mt.; for longer measurements it is possible to use modified structures designed on request.

The instrument is recommended to those who have a good manual skills and a basic mechanical back

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)